Year with you

project

customer

design

engineer

idea

pishrosanat company

Adak

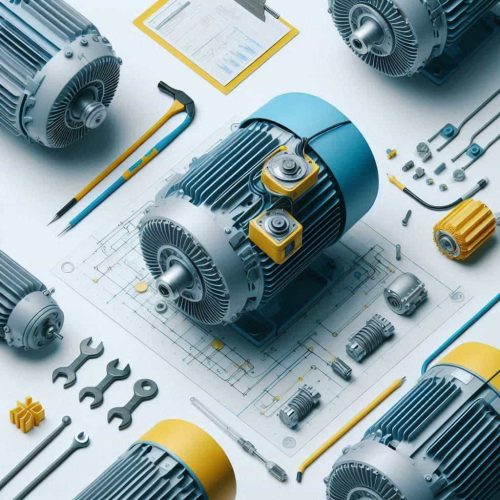

Pishro Sanat Adak Company, relying on up-to-date technical knowledge, benefiting from a specialized and experienced team, advanced equipment, and successful experiences in various industrial projects, is among the top providers of design, renovation, and overhaul services.

All kinds of electric machines are located in the country. With a knowledge-based and engineering-oriented approach, this company meets the needs of a wide range of industries, including oil and gas, petrochemicals, steel, mining, cement, automotive, and new energies.

From receiving the order to final delivery, our work processes are carefully designed and scheduled so that you have the least waiting time.

With up-to-date knowledge and a creative approach, our engineers provide designs that consume less energy and are more efficient.

Our experts ensure quality and sustainability using advanced simulation software and global standards.

With engineering design and optimal selection of materials, we reduce ancillary costs and provide you with the best quality-to-price ratio.

Benefiting from a team of experienced architects, engineers, and project managers guarantees the quality and success of projects. Our expertise is exemplary.

Our technical team is ready to provide the necessary training to your personnel and advice on system maintenance and upgrades.

Given the key and vital role of various types of industrial electric motors in production, transmission and operation processes, the reliability and availability of this equipment are of utmost importance. In many industries, including oil and gas, petrochemical, steel, cement, automotive and food industries, the continuous and uninterrupted operation of electric motors is directly related to productivity, safety and reduced operating costs. Any stoppage in the operation of these motors can lead to disruption of production lines, delays in order delivery, and in some cases even financial and environmental losses. For this reason, the selection, installation, proper operation, and preventive maintenance of this equipment are critical requirements of industrial asset management.

Electric motors are considered to be one of the most important and widely used electrical equipment in industry, and their main function is to convert electrical energy into mechanical energy. This energy conversion forms the basis of the operation of many industrial machines and equipment and is used in a wide range of applications - from small and semi-industrial devices to huge production lines and heavy equipment. These motors play a key role in automating industrial processes, increasing production efficiency, reducing dependence on human labor, and improving the accuracy and repeatability of operations. From the food, pharmaceutical, and packaging industries to mines, refineries, steel, and cement plants, they all rely on electric motors to power their equipment.

Today's electric motors are much more efficient and reliable than their older counterparts in terms of energy efficiency, engineering design, fuel economy, and advanced control capabilities. The use of new technologies, high-quality materials, and more compact designs have resulted in more stable performance, lower noise, and longer life. However, the importance of maintenance, periodic servicing, and monitoring the performance of this equipment cannot be ignored. Even the most advanced electric motors can suffer from reduced efficiency, increased energy consumption, or sudden shutdowns without a regular maintenance schedule, which will impose heavy costs on production lines. Therefore, implementing preventive and predictive maintenance programs, using condition monitoring systems, and continuously monitoring performance parameters such as temperature, vibration, and current are key measures to ensure stable and economical operation of electric motors.

Proper installation and commissioning of an electric motor is one of the key and decisive steps in the process of optimal operation of industrial equipment. This step has a direct and undeniable role in the stability of system performance, increasing the useful life of the motor, optimizing energy consumption, and preventing sudden stops and damages caused by premature failures.

We provide specialized design, refurbishment, overhaul and supply services for a wide range of electrical machinery; including all types of AC and DC electric motors, generators, medium and high voltage motors, and special industrial equipment.

Yes, our technical team is ready to provide complete installation, commissioning, testing, and initial commissioning services for equipment at the customer's site, according to IEC and NEMA standards.

Yes, technical inspection and providing expert advice before signing a contract is one of our services. Our goal is to provide an accurate and optimal solution for the customer's real needs.

We have the ability to supply and remanufacture products from reputable domestic and international brands such as Siemens, ABB, VEM, WEG, GAMAK, Motogen, Gemco, and other industrial brands.

Yes, we offer preventive and periodic maintenance (PM) contracts for organizations and factories to prevent sudden breakdowns and increase the useful life of equipment.

In the project of designing and manufacturing special engines, working with an industry leader was a professional and meticulous experience. From planning to execution, everything went according to industry standards.

Pishro Sanat Adak was one of the few companies that was able to identify and fix the problems with our electric motors in a completely professional manner. Their technical team is truly skilled and reliable.

Since we entrusted the industrial electric motor overhaul project to the industry-leading team, the efficiency of our production line has increased significantly. The expertise and commitment of this group is truly exemplary.

Electric motors are the backbone of many industrial processes.In large industries such as oil and gas, petrochemicals, steel, cement and mining, malfunctioning of this equipment can lead to production shutdowns, reduced productivity and incur heavy costs.However, there are common mistakes in maintaining these machines that, if not identified and corrected in a timely manner, can...

Get to know the industry-leading features and capabilities at a glance.

about us

With the grace of God Almighty and with its technical knowledge, up-to-date facilities, and numerous and successful experiences in the field of electric machine services, Pishro Sanat Adak Company has been able to join the ranks of the top companies providing design, renovation, manufacturing, overhaul, and supply services for all types of electric machines, and always offers the best products and services from the most famous domestic and foreign brands in accordance with the needs of industrial owners in Iran.

Ways to contact us

Copied to clipboard

We have entrusted this company with the supply of electrical parts we need several times. The quality of the parts was excellent and their response time was very good. I recommend it.