Electric motors are the backbone of many industrial processes.

In large industries such as oil and gas, petrochemicals, steel, cement and mining, malfunctioning of this equipment can lead to production shutdowns, reduced productivity and incur heavy costs.

However, there are common mistakes in maintaining these machines that, if not identified and corrected in a timely manner, can lead to serious breakdowns

In this article, we will examine five common errors in the maintenance of industrial electric motors and provide effective solutions to prevent them.

1. Over- or under-lubricating

Why is this mistake dangerous?

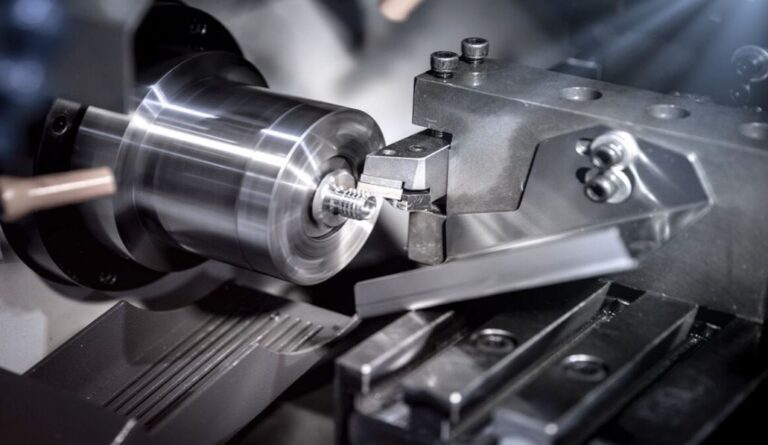

One of the most important moving components in electric motors are bearings. These parts require precise and adequate lubrication for smooth operation. However, in many industries, it is seen that either too much grease is injected or lubrication is performed at non-standard intervals. Both of these conditions can cause the bearings to overheat, grease leakage into the windings and ultimately complete failure of the motor.

Suggested solution:

Use the manufacturer's detailed instructions for the appropriate type and amount of grease.

Set a regular lubrication schedule based on environmental conditions and engine operating hours.

Use high-quality industrial lubricants appropriate for operating temperatures and bearing types.

Investigate the possibility of using automatic lubrication systems in critical engines.

2. Ignoring signs of vibration and unusual sounds

Why are these signs important?

Vibrations or unusual noises are among the first warning signs of failure in electric motors. Problems such as misalignment, shaft imbalance, loose mountings, or bearing failure can cause these vibrations. Ignoring these issues can ultimately lead to serious mechanical and electrical damage.